Project Information

Lubricant additives

02 October, 2023

Karamehmet Mah. AVRUPA SERBEST BÖLGESİ Adnan Arisoy blv. NO: 13 İÇ KAPI NO: 106

Anti-wear additive

Additive is a metal–containing additive that represents a new generation of anti-wear additives. Additive is able not only to reduce the wear of the friction pair surfaces, but also practically eliminates it, due to the formation of a self-healing, protective copper film on the friction surfaces. The secret of the Additive technology lies in the calculated and determined amount of perfectly distributed copper particles forming a protective layer on the surfaces of the friction pair.

Product Properties

The protective layer of copper film formed on the surface reduces friction, protects work surfaces from wear and corrosion.

Product Advantages

According to the test results:

- Reduced wear of parts by 54%,

- Reduction of fuel consumption up to 5%,

- Reduction of oil consumption up to 7%,

- Reduction of CO emissions,

- Increasing the oil and grease replacement interval,

- Increase the service life of parts.

Additive for greases

This organoborate serves as a boron source for a variety of applications including: adhesion promoters, antioxidants flame retardant additives, corrosion inhibitors, dehydration agents, petroleum products, polymerizing agents, tackifiers for silicone elastomers, rubber and plastic stabilizers, and as cross-linking agents in various resins.

This additive used in lubricating oils and greases. The effect of its application is:

- Improvement of anti-corrosion properties;

- Dispersancy

- Increase of thermal stability and resistance to destruction;

- Friction and wear reduction.

- Increase the drop point.

Properties | |

Purity, % (min.) | 98 |

Molecular Weight [g/mol] | 398.47 |

Boron, % | 2.71 |

Physical State | Clear colorless liquid |

Density @ 26 oC [g/ml] | 0.860 |

Boiling Point, (10 mmHg) [oC] | 210 |

Viscosity @ 40 oC [cst] | 5.9 |

Refractive index, n25/D | 1.4375 |

Flash Point, [F] | 257 |

It is a high-quality analogue of the applicability of such products manufactured in the USA as: Almabor 2EHB (Anderson), 5370C (Lubrizol).

Corrosion inhibitor for ferrous metals

Application

Highly effective corrosion inhibitor of ferrous metals of domestic production. The reagent is perfectly soluble in water of various hardness, compatible with most chemical reagents, does not cause foam formation. It acts as a replacement for sodium nitrite. It is used to suppress corrosion of ferrous metals in various aqueous media, for example, in metal processing, in the production of reagents in tinned steel aerosol packaging, for water-cooled systems, etc., it is a high-quality analogue of the additive Crodacor be-lq (Croda Plc, UK).

Specifications

- Viscous liquid from colorless to brown;

- Mixed with water in any ratio to form a clear solution;

- The pH of the reagent solution with a mass fraction of 1% is 9.5 ± 1.0;

- Specific gravity of the drug at 25 °C 1.20 ± 0.5 g/cm3.

Recommendations for use

The consumption of the drug depends on the conditions of use and is 1-10 g per liter of working solution.

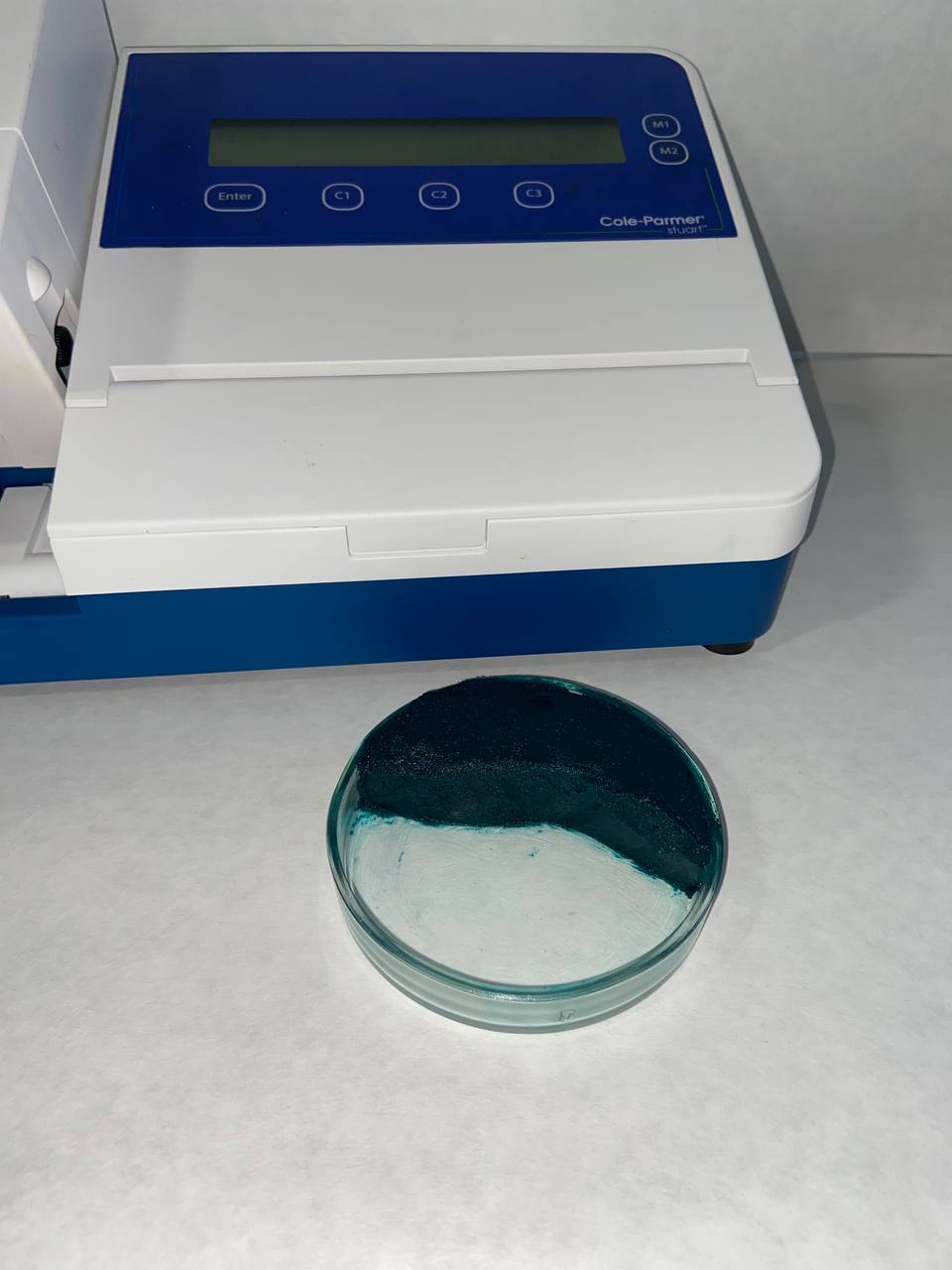

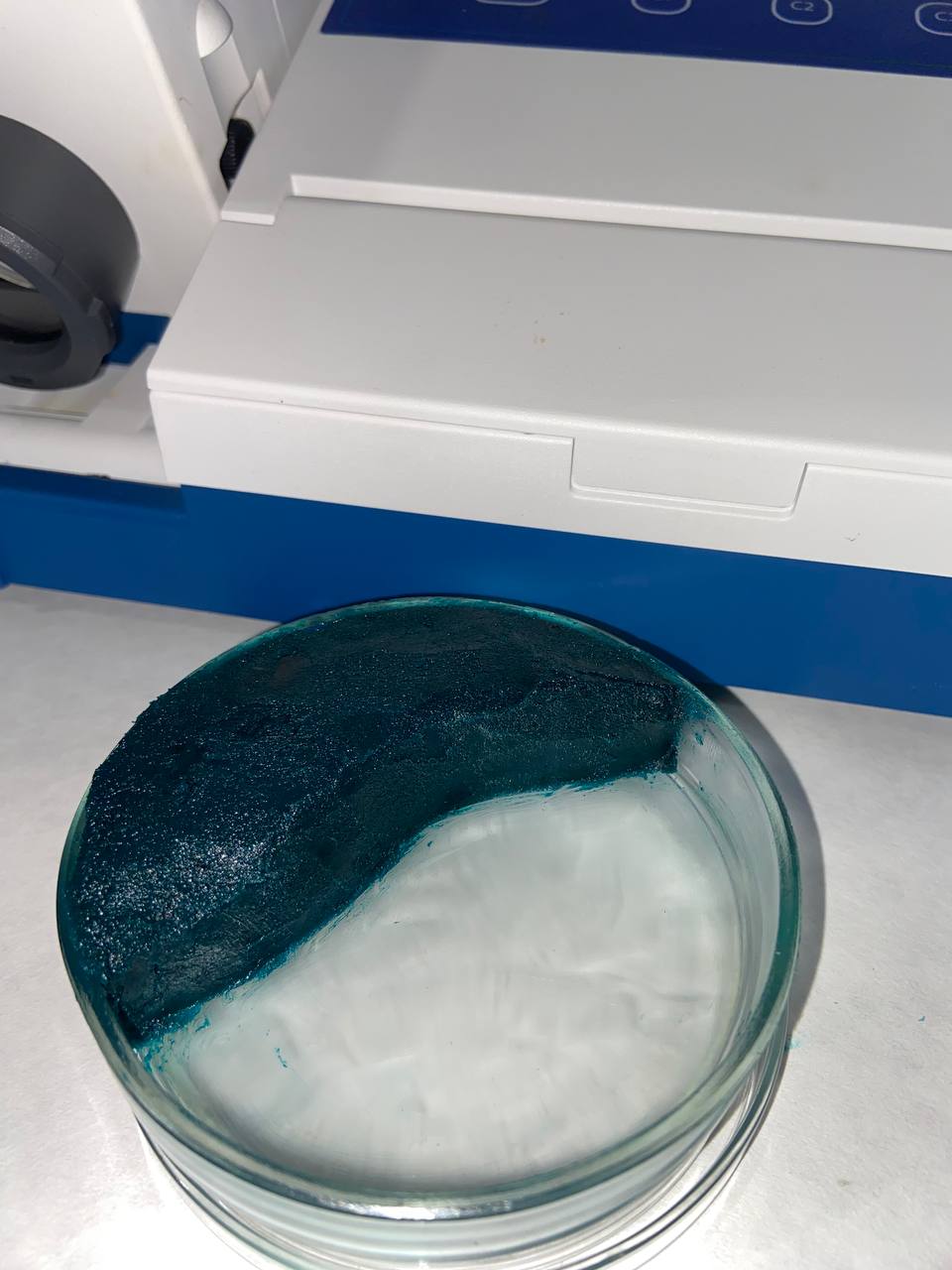

The figure shows an example of the application of in a working concentration of 5 g per liter of working solution. Corrosion tests were carried out when standard plates (steel 20) were aged in distilled water (a, b) and in a solution of sodium chloride concentration of 250 mg/l (c, d) at a temperature of 55 ° C for 15 days. The data of the idle experiment without the addition of are presented in Figures a and B.

Demonstration of the appearance of test plates (steel 20) after corrosion tests in various aqueous media with the addition of (b, d) and without it (a, c)

Storage conditions and warranty period

Corrosion inhibitor for ferrous metals should be stored in indoor ventilated warehouses.

The warranty period of storage is 12 months from the date of manufacture.

Store in hermetically sealed containers in a well-ventilated, cool, dry and dark room.

Low-toxic solvent

Description

A low-toxic solvent of domestic production for use as an alternative to imported products such as N-methylpyrrolidone or D-limonene. The product has a high solvent capacity, is compatible with most organic solvents, does not have a sharp unpleasant odor. It has a high cowry-butanol index. Due to these properties, solvent is perfectly suitable for use:

- as a base for the production of industrial detergents (removal of old paint, graffiti, traces of bitumen and other fat-and-oil contaminants),

- as a low-toxic plasticizer for plastics, including polyvinyl chloride, for humans and the environment (eco-friendly replacement of phthalates),

- as a base solvent or co-solvent for the paint industry,

- as an additive to fuels and oils,

- as a component in the production of agricultural chemicals, etc.

This product is similar to the Prifer 6813 product (Croda International plc. British).

Properties

- Mobile transparent liquid of light yellow color;

- Does not mix with water;

- The content of the main fraction is not less than 92%;

- Refractive index(nD20) 1.490±0.010;

- The density of the drug at 20oC 0.97 ± 0.02 g / cm3;

- Kinematic viscosity at 25 ° C 6.0 ± 0.5;

- Kinematic viscosity at 40 ° C 4.0 ± 0.5;

- Boiling point not lower than 220 ° C;

- The boiling point of the main fraction is 313 ° C;

- Melting point below minus 50 °C;

- The flash point in an open crucible is not lower than 110 ° C.

Storage conditions and warranty period

Low-toxic solvent should be stored in indoor ventilated warehouses.

The warranty period of storage is 36 months from the date of manufacture.

Store in hermetically sealed containers in a well-ventilated, cool, dry and dark room.

Biocide

Application

The reagent is a non–oxidizing broad-spectrum biocide. It has strong biocidal properties against bacteria, fungi and algae. It is used as a biocide for industrial water use systems. Recommended for reverse osmosis equipment and for cutting emulsion, cutting fluid, lubricating fluid, cooling mixture, metal-cutting [metal working] oil.

Specifications

It is a stabilized aqueous solution of isothiazolones.

– Transparent liquid of light yellow color.

– Mass fraction of the main substance is not less than 6.5%.

– Density of 1.2-1.3 g / cm3.

– Non-flammable, fire- and explosion-proof.

Recommendations for use

The reagent is added to the treated water constantly or periodically.

With continuous supply of the reagent, the usual dose is from 10 to 50 mg / l for 1-2 weeks. With a high degree of contamination, it is recommended to use "shock doses" of 100-400 mg/l. In the future, the maintenance dose of the reagent is 25-50 mg / l.

With periodic dosing, the required amount of reagent is 100-200 mg/l once or twice a week.

Features

High biocidal efficiency in a wide range of pH values (2-9.5), biodegradability.

Storage conditions and warranty period

Biocide is stored in dry, cool, well-ventilated rooms, protected from direct sunlight, at temperatures from -5 ° C to +40 ° C.

The warranty period of storage in undisturbed packaging is 12 months from the date of manufacture.